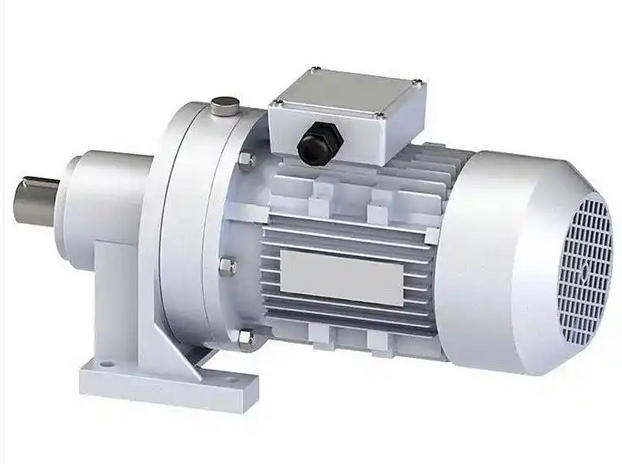

Introduction to the possible causes of WB100-D-23-0.55KW micro cycloidal reducer malfunction

There are many reasons why the WB100-D-23-0.55KW micro cycloidal reducer may malfunction, and the following are some common factors:

1. Lubrication issues

Insufficient lubrication: Insufficient lubricating oil can cause increased friction between components, resulting in poor protection and heat dissipation, accelerating wear and leading to malfunctions such as gear wear and bearing damage.

Poor oil quality: The quality of the lubricating oil used is poor, or the lubricating oil has not been replaced for a long time, containing impurities, moisture, etc., which will reduce the lubrication effect, increase the wear of components, and may also cause blockage of the lubrication system.

Incorrect selection of lubricating oil: If the selected lubricating oil does not meet the requirements of the gearbox, such as inappropriate viscosity, it will not form a good lubricating film on the surface of the components and will also affect the normal operation of the gearbox.

2. Overload operation: When the load borne by the reducer exceeds its rated load, it will cause excessive pressure on internal components such as gears and bearings, which can easily lead to gear wear, fracture, bearing heating, damage and other faults. For example, in situations where there is a sudden high load during device startup, or where the gearbox is used to drive loads exceeding its rated power for a long time.

3. Improper installation

Axis misalignment: When installing a reducer, if the axis between the input shaft and the motor shaft, or between the output shaft and the load shaft, is misaligned, it will cause poor gear meshing and additional stress on the shaft, leading to increased gear wear, premature bearing damage, and abnormal noise and vibration.

Unstable installation foundation: The installation foundation of the reducer is not firm enough, which can cause vibration during operation, affecting the normal operation of internal components of the reducer, accelerating component wear, and even causing loose connecting parts, leading to malfunctions.

4. Bearing malfunction

Poor lubrication: Lack of good lubrication in bearings can increase friction, generate heat, accelerate bearing wear, and in severe cases, may lead to bearing jamming.

Improper installation: When installing bearings, if the installation method is incorrect, such as excessive force or improper installation, it can damage the internal parts of the bearing and affect its normal service life.

Overloading: When the load borne by the bearing exceeds its rated load, it can cause premature wear, fatigue, and even damage to the bearing.

5. Gear malfunction

Wear and tear: Long term operation or use under high load and harsh working conditions can cause wear and tear on gear components such as cycloid gears and needle teeth, leading to increased backlash, decreased transmission accuracy, and even problems such as slipping and inability to transmit power normally.

Tooth breakage: When gears are subjected to excessive impact loads or have quality defects such as poor material properties or improper heat treatment, it may cause gear tooth breakage, making the reducer unable to function properly.

Tooth surface damage: The tooth surface may experience fatigue pitting, bonding, and other damage phenomena, mainly due to poor lubrication, excessive load, and low gear meshing accuracy, which can affect the transmission efficiency and service life of the gear.