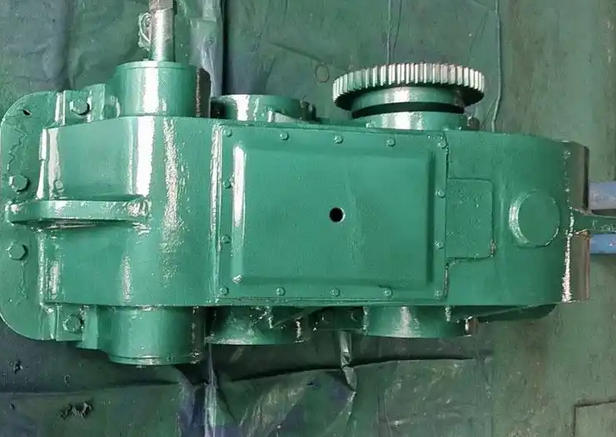

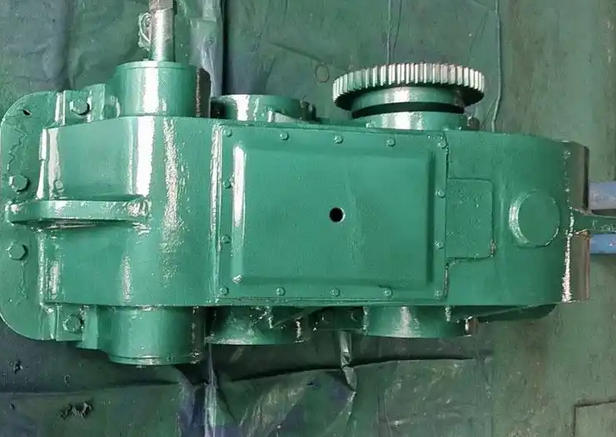

What are the reasons for lubricating oil leakage in ZQD400-160-I-Z soft tooth surface reducer

The causes of lubricating oil leakage in ZQD400-160-I-Z soft tooth surface reducers are similar to most soft tooth surface reducers. The core focus is on sealing failure, assembly and installation deviation, improper lubrication management, equipment aging and manufacturing defects, and abnormal operating conditions, as follows:

1. Sealing related failure

Sealing components themselves: The skeleton oil seal at the shaft end and the sealing gasket on the box joint surface are the core sealing components. During long-term operation of the gearbox, the sealing components may experience aging, hardening, cracking, and other conditions due to the chemical action of lubricating oil and the high temperature generated by gear operation; At the same time, the rotation of the gear drives continuous friction between the shaft and the oil seal, which can cause wear on the lip of the oil seal and cause the seal to lose its sealing ability. If the selection of sealing components is improper and ordinary rubber components that are not resistant to oil and temperature are used instead of compatible fluororubber components, it will also accelerate the failure of the seal and cause leakage.

Sealing auxiliary structure failure: blockage of the breathing valve (vent hole) is a common cause. When the gearbox is running, the oil temperature rises and the air inside the box expands, causing the pressure to increase. If the breathing valve is blocked by oil and dust, the internal pressure cannot be released, and the oil will be "pressed out" of the weak sealing part by the pressure. In addition, if the glass at the oil mark cracks, the sealing ring around it will age and harden, which will also allow oil to leak from the sight glass position.

2. Insufficient assembly and installation accuracy

Improper assembly of components: If the oil seal is not pressed vertically during installation, it may become skewed or the lip may be scratched by the shaft shoulder, which can cause the oil seal to not fit tightly against the shaft surface; Failure to clean up oil stains and old glue on the joint surface of the box before assembly, uneven or broken sealant application, or failure to tighten bolts in diagonal order can result in uneven stress and gaps on the joint surface. In addition, improper pre tightening force during bearing installation can cause radial runout after bearing wear, driving the shaft neck to rotate eccentrically and causing uneven force on the oil seal lip, indirectly leading to leakage.

Overall installation deviation: If the reducer is not accurately aligned with the motor or working machine during installation, or if the base is not firmly fixed, severe vibration will occur during operation. This kind of vibration will gradually loosen the fixing bolts of the end cap and box, and also intensify the wear of the seals, ultimately causing oil to leak from the loose gaps or damaged seals.

3. Improper lubrication management

Inappropriate oil quantity and oil type: It is a common mistake to add oil beyond the upper limit of the oil gauge. Excessive lubricating oil will be violently stirred during gear operation, and a large amount will accumulate on the shaft seal, housing joint surface, and other parts, which is prone to overflow and leakage. Meanwhile, if the viscosity of the selected lubricating oil is too low, the oil is prone to penetrate through the sealing gap; If the oil deteriorates, mixes with moisture or impurities, it will not only reduce the lubrication effect, but also corrode the seals, indirectly increasing the risk of leakage.

4. Equipment aging and manufacturing defects

Aging and wear of core components: After long-term use, scratches, rust, or grooves may appear on the shaft neck in contact with the oil seal due to friction, damaging the flatness of the sealing surface and causing oil to seep out from the gap; The box may also undergo slight deformation due to long-term temperature differences and heavy load operation, resulting in poor adhesion of the joint surface and the formation of oil leakage channels. In addition, the increased clearance after bearing wear will drive the shaft to eccentricity during operation, further damaging the sealing environment and causing leakage.