What impact will the vibration of the motor and ZSY160-28-IN reducer have on production efficiency

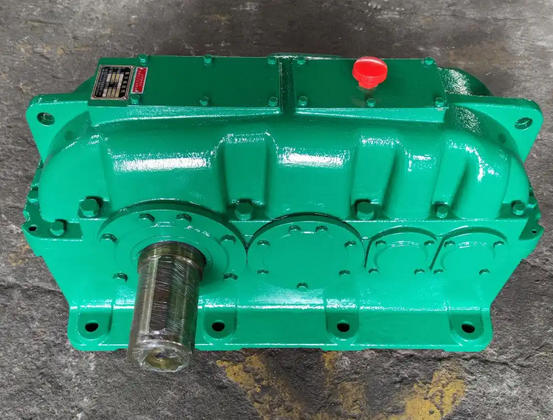

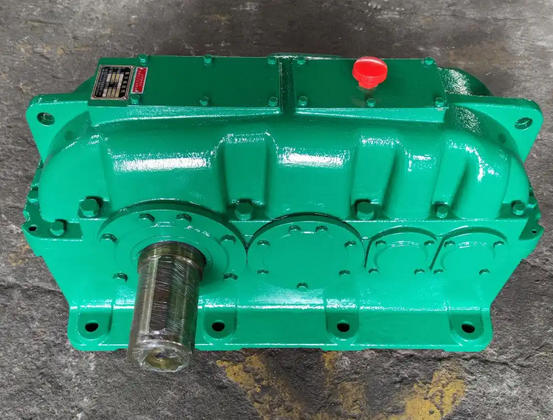

The vibration of the motor and ZSY160-28-IN reducer (hard tooth surface cylindrical gear reducer, transmission ratio 28, installation form IN) is a key factor affecting efficiency in industrial production. Its hazards run through the entire production process, from the equipment itself to production capacity, quality, and cost, and will have a chain reaction. Based on the structural characteristics of this type of reducer (hard tooth surface gear, high-speed/low-speed shaft double support, box structure) and industrial application scenarios, the 8 core impacts of vibration on production efficiency are listed in detail, each with specific mechanisms and practical consequences:

1. Accelerate equipment component wear and failure, resulting in extended unplanned downtime

The hard toothed gears, bearings (high-speed shafts are mostly deep groove ball bearings, low-speed shafts are self-aligning roller bearings), couplings and other core components of ZSY160-28-IN reducer are extremely sensitive to vibration:

Vibration can damage the stability of the oil film on the gear meshing surface, resulting in uneven contact stress on the tooth surface. Hard tooth surfaces are prone to pitting, bonding, and even tooth breakage (this model has a transmission ratio of 28 and high low-speed shaft torque, and vibration can amplify the impact of tooth surface load);

The impact friction between the rolling elements of the bearing and the inner and outer rings intensifies, resulting in deformation of the cage, wear of the raceway, and ultimately the bearing getting stuck. To replace the bearings of this type of reducer, the housing and gear shaft need to be disassembled, and the repair time for a single unit is usually 4-8 hours;

Vibration can also cause loosening of coupling bolts and wear of key slots, leading to further expansion of coaxiality deviation between the motor and gearbox, forming a vicious cycle of "vibration deviation vibration". Unplanned shutdown frequency can increase by more than 30%, directly causing production line interruption and significant capacity loss.

2. Reduce transmission efficiency, increase energy consumption and operating costs

The design transmission efficiency of ZSY160-28-IN reducer is about 94% -96% (with high meshing efficiency of hard tooth gears), but vibration will directly damage this optimized state:

The vibration during gear meshing can generate additional impact loads, resulting in a decrease in meshing efficiency. At the same time, bearing vibration increases friction losses, and the overall transmission efficiency may decrease by 5% -10%;

To maintain output speed and torque, the motor needs to consume additional electrical energy to compensate for losses. Taking a matching motor with a rated power of 37 kW as an example, the annual additional power consumption caused by vibration can reach 15000-25000 kWh;

Long term high vibration can accelerate the aging of lubricating oil (the heat generated by vibration and the stirring effect damage the oil quality), shorten the replacement cycle of lubricating oil by 50%, and indirectly increase maintenance costs.