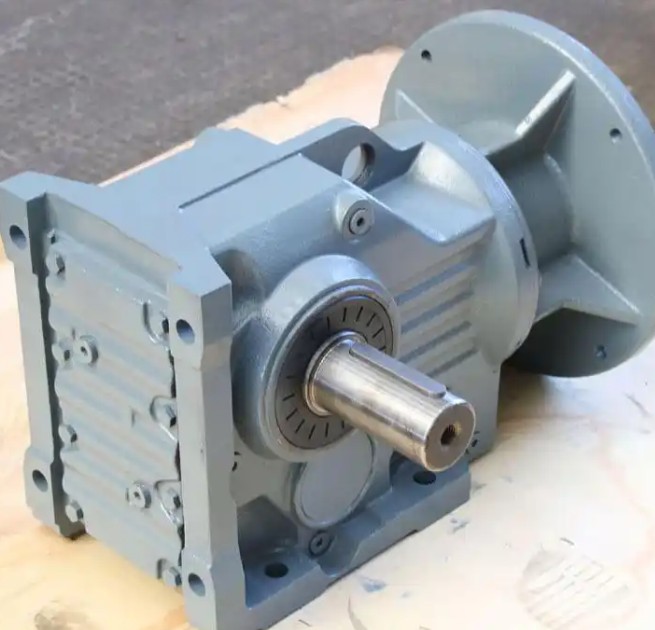

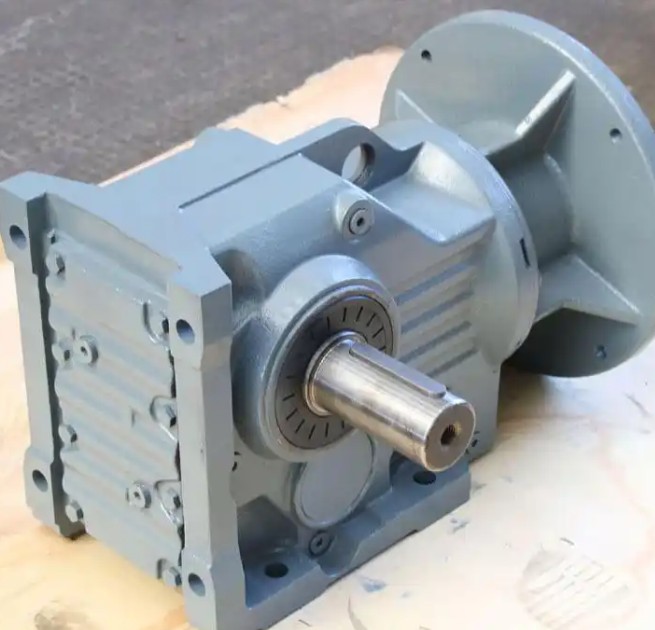

How does the splash lubrication system of K47-Y0.55-4P-46.03-M5-I-B gear reducer work

The splash lubrication system of K47-Y0.55-4P-46.03-M5-I-B gear reducer relies on the lubrication and heat dissipation of transmission components such as gears and bearings through the oil carrying and oil throwing effects during high-speed rotation of the gears. It belongs to a passive lubrication method and does not require additional forced lubrication devices such as oil pumps and pipelines. The structure is simple and highly reliable, suitable for the lubrication needs of low-power (0.55kW) and low-speed working conditions of this model. The specific workflow is as follows:

1. Oil storage and carrying process

There is an oil tank at the bottom of the gearbox body, and during assembly, lubricating oil of the specified grade (such as industrial gear oil L-CKC series) should be added according to the oil level mark. The oil level height should ensure that the tooth root of the low-speed gear is immersed in the oil (the immersion depth is usually 1/3~1/2 of the tooth height, and the specific reference should be made to the gearbox manual of that type). When the motor drives the input shaft of the reducer to operate, the gears at all levels rotate accordingly. During the rotation of the low-speed gear, the teeth will continue to lift the lubricating oil in the oil pool.

2. Oil slinging and oil distribution process

High speed rotating gears generate centrifugal force, which splashes lubricating oil adhered to the tooth surface in all directions, forming oil mist and droplets. Part of the oil is directly thrown towards the meshing tooth surface, forming an oil film in the gear meshing area, lubricating the meshing tooth surface and reducing friction and wear; Another part of the oil splashes onto the inner wall of the gearbox, and then flows along the inner wall to the oil groove or bearing end face of the bearing seat, providing lubrication for the rolling elements (rollers/steel balls) and raceway of the bearing.

For the hard tooth gear structure of K47 model, splashing oil can also wash away debris and other impurities on the tooth surface, playing a cleaning role. After the impurities flow back to the oil pool with the oil, they can be regularly discharged through the oil drain port at the bottom of the oil pool.

3. Reflux and circulation process

After completing the lubrication and heat dissipation of gears and bearings, the oil participating in lubrication will flow back to the oil pool at the bottom of the box along the surface of the components under the action of gravity, and be carried up by the rotating gears again, forming a continuous internal circulation lubrication.

4. Adaptation to working conditions and precautions

The transmission ratio of this model of reducer is 46.03, which belongs to a large transmission ratio structure. The low-speed gear speed is relatively low, so oil level control is particularly critical - a low oil level can lead to insufficient oil carrying and ineffective lubrication; If the oil level is too high, it will increase the resistance of gear oil stirring, resulting in increased power loss and oil temperature rise.