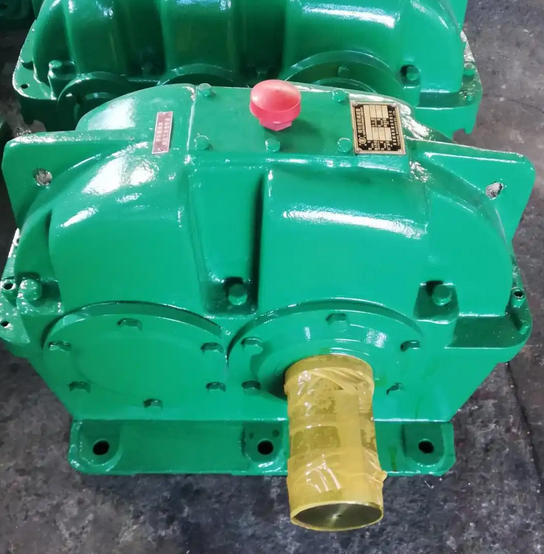

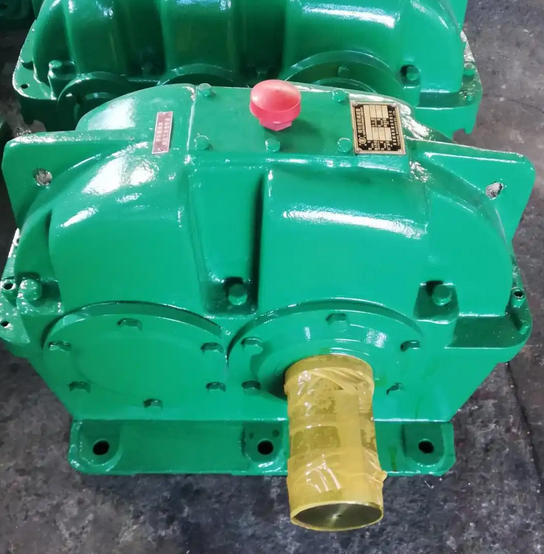

What range of horizontal deviation has a relatively small impact on the transmission efficiency of ZDY315-5-1 reducer

The horizontal deviation of the ZDY315-5-1 reducer and motor should be controlled within ≤ 0.05mm/m (both longitudinal and transverse must be met), which has minimal impact on transmission efficiency (efficiency loss ≤ 1%), and is the optimal control range for industrial scenarios.

Deviation interval corresponds to efficiency impact

Ideal range (≤ 0.02mm/m): Efficiency loss is almost negligible (≤ 0.3%), gears and bearings are uniformly stressed, and the transmission state is close to the optimal design value, suitable for high-precision, high load continuous operation scenarios.

Safe range (0.02-0.05mm/m): Efficiency loss between 0.3% -1%, equipment operation without obvious vibration or abnormal noise, component wear at normal levels, is a conventional standard that balances cost and performance.

Critical range (0.05-0.1mm/m): Efficiency loss increases to 1% -3%, local contact unevenness occurs in gear meshing, shaft bearing force increases, and long-term operation will accelerate wear, requiring timely adjustment.

Dangerous range (>0.1mm/m): Efficiency loss exceeding 3%, accompanied by significant vibration and energy waste, may also cause coupling offset, gear pitting and other faults, seriously affecting equipment life.