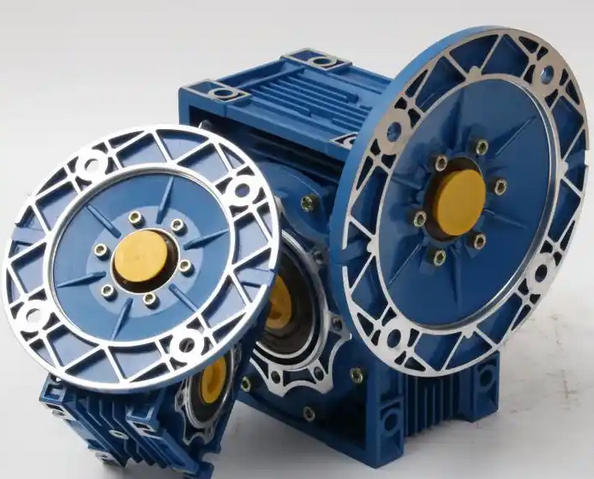

How to evaluate the self-locking performance of RV150-20-7.5KW worm gear reducer specifically

The evaluation of the self-locking performance of RV150-20-7.5KW worm gear reducer needs to be based on three core dimensions: design parameters, theoretical conditions, and actual working conditions. The conclusion is that the theoretical self-locking ability is weak, and it only has limited self-locking ability under specific working conditions. It is strictly prohibited to use it as the only braking method. The specific analysis is as follows:

1. Core design parameters determine the theoretical upper limit of self-locking

This model of reducer has a reduction ratio of 20:1 and is suitable for high-power and high torque output scenarios of 7.5KW. It is usually equipped with multi head worm gears (commonly double or triple head). The worm lead angle is a key indicator that determines self-locking.

20: When using a multi head worm gear with a reduction ratio, the lead angle is usually between 8 ° -12 °, much higher than the self-locking critical value (the lead angle should be ≤ 3.5 °); At the same time, its transmission efficiency can reach 65% -75% (far higher than the self-locking requirement of<50%), which theoretically does not meet the self-locking condition of "lead angle<equivalent friction angle" and has no inherent self-locking ability.

2. Limited self-locking phenomenon under special working conditions

In practical applications, if the following stringent conditions are met, the gearbox may exhibit a brief and limited static self-locking effect:

(1) Lubrication state: Using high viscosity extreme pressure gear oil, the friction coefficient of the tooth surface increases, the equivalent friction angle increases, and the lead angle can be temporarily matched;

(2) Load and speed: in light load (≤ 30% rated load), static shutdown state, without impact or vibration interference;

(3) Component status: The worm gear is not worn, the meshing clearance is at the design lower limit (0.15-0.25mm), and there is no axial movement.

But this kind of self-locking is extremely unstable. Once the load fluctuates, the oil temperature changes, or the tooth surface wears, the self-locking ability will be immediately lost, and it does not have engineering application reliability.