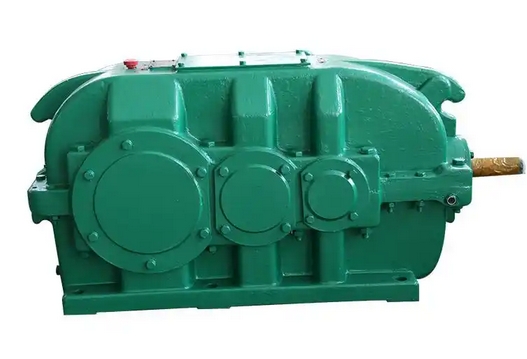

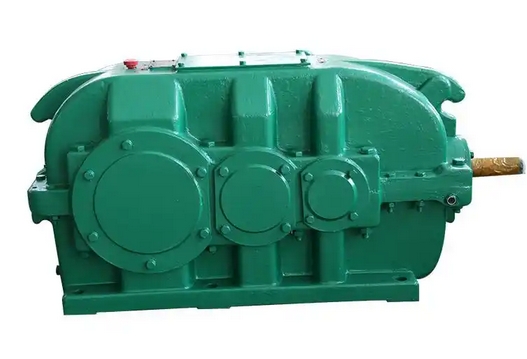

How to address the abnormal noise issue with the bearings of the hard-toothed DCY560-22.4-3N reducer

To solve the abnormal bearing noise problem of the DCY560-22.4-3N reducer with hard tooth surface, the following aspects can be taken into account:

Check the lubrication condition

Ensure the oil level is normal: Check the oil level of the gearbox. If the oil level is too low, add lubricating oil that meets the requirements to the appropriate level.

Ensure good oil quality: Regularly check the quality of lubricating oil, and if oil deterioration or contamination is found, it should be replaced in a timely manner. At the same time, to prevent impurities from entering the interior of the gearbox, the ventilation holes and oil filters of the gearbox can be cleaned regularly.

Adjust the bearing clearance

For bearings with adjustable clearance, use professional tools and methods to adjust the clearance according to the technical requirements of the reducer. If the bearing clearance is too large, it will cause unstable operation and generate noise; If the clearance is too small, it may cause overheating and increased wear of the bearing, as well as generate noise. After adjustment, it is necessary to ensure that the bearing operates flexibly without any jamming phenomenon.

If the bearing clearance cannot be restored to the normal range through adjustment, or if there is still abnormal noise after adjustment, it may be that the bearing is damaged and needs to be replaced with a new one.

Check the bearings and related components

Check the bearing condition: Carefully inspect the ball bearings, raceways, cages, and other components of the bearing. If there are signs of wear, cracks, deformation, rust, or other damage, it is necessary to replace them with high-quality bearings of the same model and specifications in a timely manner.

Check relevant components: At the same time, check the shaft neck and bearing seat hole that match the bearing. If there is wear or deformation, it will affect the installation accuracy and operational performance of the bearing, and repair or replacement is needed. For example, journal wear can be repaired by electroplating, brushing, and other methods, while bearing seat hole wear can be treated by embedding or other methods.

Improve assembly accuracy

When installing the bearings and other components of the reducer, it is necessary to strictly follow the assembly process requirements to ensure accurate installation positions of each component, concentricity, and dynamic balance. For example, using high-precision measuring tools such as dial indicators to detect and adjust the coaxiality and perpendicularity of the shaft system.

During the assembly process, attention should be paid to avoiding damage to the shaft such as bumps, scratches, etc., while ensuring that the bearings are installed in place to avoid situations such as deviation or incomplete installation.

Tighten the connecting components

Check whether the bearing cover, anchor bolts, and other connecting components of the reducer are loose. If they are loose, they should be tightened in a timely manner to prevent vibration and noise caused by loose connections.

For the sealing part, it is necessary to check whether the installation of the seals is correct and whether there is any damage. If there is a problem, the seals should be replaced in a timely manner to prevent lubricating oil leakage and prevent impurities from entering the bearings.