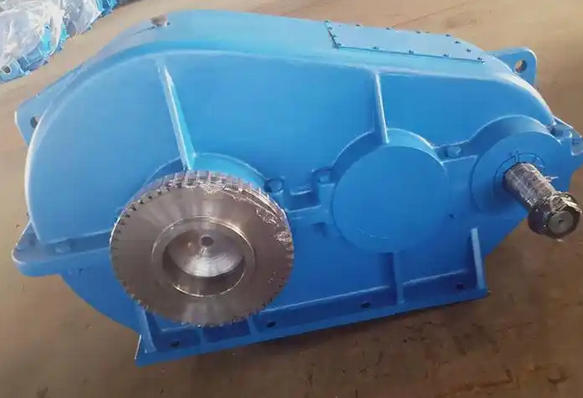

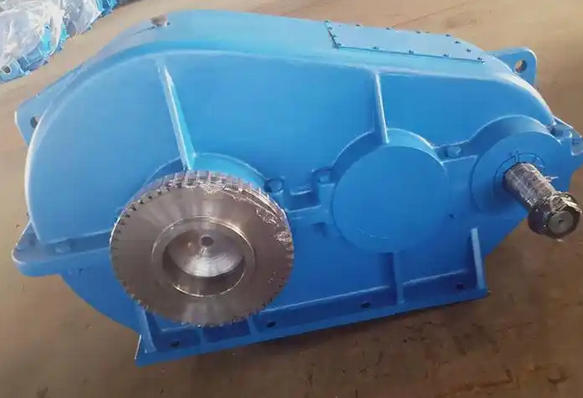

What are the specific preventive measures for abnormal operating conditions of ZQD650-291.19-3CA soft tooth surface reducer

The abnormal operating conditions of ZQD650-291.19-3CA soft tooth surface reducer are mainly reflected in overload impact, abnormal speed, harsh environment, and lubrication failure. Combined with the structural characteristics and industrial application scenarios of soft tooth surface reducer, the following targeted measures can be taken to prevent and ensure the stable operation of the equipment:

1. Dealing with overload and impact load conditions

Optimization selection and load control: In the early stage, it is necessary to accurately calculate the static load, dynamic load, and impact load during equipment operation to ensure that the rated load of the reducer is greater than the actual maximum working load. If used in scenarios such as crushers and conveyor belts that are prone to sudden heavy loads, elastic couplings can be used to buffer the impact during start stop and operation, reducing damage to gears and bearings. At the same time, avoid frequent start stop of equipment, set reasonable standby mode for intermittent working equipment, and reduce the damage caused by alternating loads.

Install protective device: Install a torque limiter to set the triggering torque to around 130% of the rated value, and promptly cut off power transmission when the load exceeds the standard; Paired with a thermal relay, it prevents overload from causing a surge in motor current and overheating of the gearbox, thus avoiding damage to internal components caused by overload from the source.

2. Dealing with abnormal rotational speed conditions

Strictly control the speed range: operate strictly according to the rated speed specified in the equipment manual, prevent overspeed operation, and prevent gear meshing frequency from being too high and friction heating from intensifying, leading to tooth surface adhesion. For scenarios such as mixing equipment that are prone to low-speed and heavy loads, regularly check the material status to avoid jamming and causing gearbox blockage. If there are signs of blockage, immediately stop the machine for cleaning to prevent the formation of gear oil film and dry friction wear.

Optimize assembly and gap adjustment: During assembly, use a laser alignment instrument to calibrate the coaxiality of the reducer, motor, and working machine, ensuring that the error is controlled within 0.05mm. At the same time, adjust the gear mesh clearance and bearing clearance according to the standard, for example, refer to the formula "backlash=0.0025 × center distance+0.05" to adjust the gear clearance, to avoid uneven force on components during speed operation due to abnormal clearance, which may cause abnormal working conditions.

3. Dealing with harsh environmental conditions

Protection against high/low temperature environments: Under normal operating conditions, the temperature of the gearbox casing should be below 75 ℃. If used in high-temperature environments such as metallurgical furnaces, a forced cooling device such as an oil pump circulation cooling system should be installed, and the dust on the cooling fins should be regularly cleaned; Choose molybdenum disulfide grease or synthetic lubricating oil with a temperature resistance of ≥ 180 ℃. If in low-temperature environments such as cold storage, use lubricating oil with good low-temperature fluidity and install an electric heater to avoid lubricating oil solidification and seal hardening affecting operation.

Protection against damp/dusty/corrosive environments: In damp or corrosive environments such as mines and chemical plants, apply anti rust coating to the interior of the gearbox, apply molybdenum disulfide grease to the bolt connections to prevent electrochemical corrosion, and open the drain valve weekly to discharge condensed water. For scenarios with high dust levels, a labyrinth sealing structure is adopted, and a cyclone dust removal device is installed at the air inlet to shorten the lubricant replacement cycle to 60% of the standard operating conditions. The respirator filter element is regularly cleaned to prevent dust from entering and exacerbating component wear.