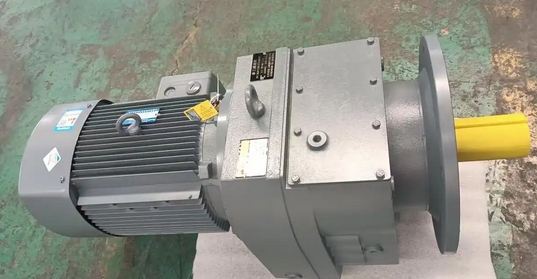

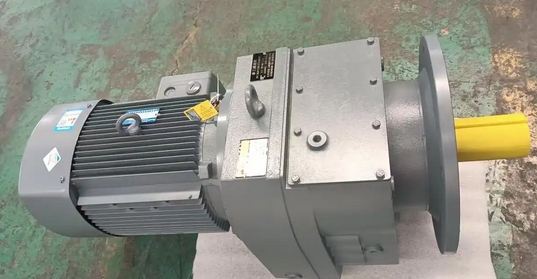

How to optimize the maintenance process for the RF27-0.75KW-105 reducer

Here are some methods to optimize the maintenance process of RF27-0.75KW-105 gearbox:

Develop a detailed maintenance plan

Determine a scientifically reasonable maintenance cycle based on factors such as the frequency of use, load conditions, and working environment of the gearbox. For this type of gearbox that operates continuously, it is recommended to perform routine maintenance every 1000 to 2000 hours of operation; For intermittent work, the maintenance cycle can be appropriately extended according to actual usage.

Clearly define the maintenance content, including specific items such as cleaning, lubrication, inspection, and adjustment, and develop corresponding operating specifications and standards.

Optimize maintenance steps

Cleaning: Regularly clean the dust and impurities inside the gearbox casing to prevent dirt from entering the gear meshing area and reduce wear. You can use a clean cloth to wipe off surface dust and oil stains. For difficult to remove oil stains, you can use an appropriate amount of specialized cleaning agent, but be careful to avoid the cleaning agent coming into contact with internal electrical components. At the same time, it is necessary to ensure that the cooling system of the reducer, such as the radiator and ventilation openings, is kept clean to ensure smooth air circulation and avoid overheating caused by poor cooling.

Lubrication: Choose lubricants suitable for the working environment and load of the gearbox, refer to the recommendations of the gearbox manufacturer, and clarify the model, viscosity, and other parameters of the lubricating oil. Regularly check the quality and oil level of lubricating oil. If the oil becomes black, thick, has impurities, or the oil level is too low, it should be replenished or replaced in a timely manner. In general, the lubricating oil of the gearbox should be replaced every six months to one year. After a running in period of 7-14 days (150-300 hours), the new gearbox needs to be replaced with new oil, and it must be replaced again after three months of use. In the future use, gearboxes that work continuously for a long time can have their oil replaced every 6-8 months, and gearboxes that work for no more than 8 hours a day can have their oil replaced every 10-12 months. When replacing the lubricating oil, the old oil should be drained first, then the inside of the gearbox should be cleaned with a cleaning agent, and finally new lubricating oil should be added.

Check:

Fasteners: Regularly inspect the fasteners of the gearbox, including anchor bolts, connecting bolts, etc., to ensure that they are in the correct position and tightened. If there are loose or damaged fasteners, they should be replaced in a timely manner.

Bearings and seals: Regularly check the temperature, noise, and vibration of the bearings, as well as whether the seals are intact, to ensure that the lubricating oil does not leak and to prevent external debris from entering. If abnormal noise, vibration or damaged seals are found in the bearings, they should be repaired or replaced in a timely manner.

Gear: Regularly open the gearbox housing to check the wear of the gears and inspect for cracks, tooth surface wear, and other issues. If severe gear wear is found, it should be replaced in a timely manner.