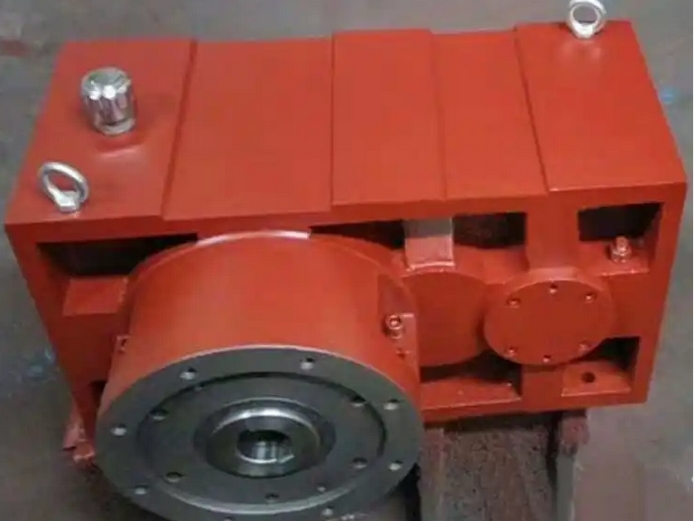

Daily maintenance of lubrication and sealing system for ZLYJ125-10-II reducer used in screw extruder

The following are the daily maintenance points for the lubrication and sealing system of the ZLYJ125-10-II reducer used in screw extruders:

Daily maintenance of lubrication system

Oil level check: Regularly check the oil level of the gearbox to ensure that the oil level is between the upper and lower markings of the vernier scale. Insufficient oil can lead to insufficient lubrication and reduce the service life of parts; Excessive oil can cause high heat generation and energy consumption, and the oil is prone to deterioration, which also leads to lubrication failure.

Oil inspection: Regularly check the quality of lubricating oil, observe the color and transparency of the oil, smell its odor, and determine whether there are impurities, pollution, decomposition, or aging. If the oil is found to have deteriorated, it should be replaced in a timely manner. For gearboxes that work continuously for a long time, the oil can generally be replaced every 6-8 months; Gearboxes that work no more than 8 hours per day can be replaced every 10-12 months. When the new gearbox is first used, after a running in period of 7-14 days (150-300 hours), it must be replaced with new oil. After using it for 3 months, it needs to be replaced with new oil again.

Oil temperature monitoring: Pay attention to the oil temperature during the operation of the gearbox. Under normal circumstances, the oil temperature should not be too high. If the temperature of the box is too high, it should be checked whether the oil level is too high, the surrounding heat dissipation conditions are poor, the oil quality is aging, or the cooling water volume is insufficient, or the cooling effect is poor due to scaling in the cooling coil.

Lubrication point inspection: Regularly inspect the lubrication points inside the gearbox, such as gears and bearings, to ensure that the lubricating oil can be supplied to these parts normally and ensure their smooth operation.

Oil filter inspection: For gearboxes lubricated with circulating oil, the oil pressure should be checked regularly. When the oil pressure drops significantly, the oil filter should be checked and cleaned to prevent blockage and affect the circulation and filtration effect of lubricating oil.

Daily maintenance of sealing system

Appearance inspection: Regularly check the sealing parts of the reducer, including the joint surface of the box and the shaft end seal, to observe whether there is any oil leakage or seepage. If oil leakage is found on the high-speed shaft, check if the oil level is too high; If the shaft seal leaks oil due to aging or wear, appropriate butter can be injected through the grease nozzle on the cover. If the oil leakage is severe, the oil seal should be replaced promptly by oneself.

Cleaning the sealing surface: Regularly clean the sealing area of dust, oil stains, and debris to prevent these impurities from entering the sealing gap, exacerbating the wear of the sealing components and affecting the sealing effect.

Preventing collision damage: During daily operation and maintenance, attention should be paid to avoiding collisions or mechanical damage to the sealing parts to avoid damaging the sealing performance.

Seal replacement: Regularly replace seals based on their usage and aging level. Generally speaking, after a certain period of use, even if there is no obvious leakage, it is recommended to perform preventive replacement of vulnerable seals such as oil seals to ensure the reliability of the sealing system. When replacing seals, it is necessary to choose products with the same specifications and materials as the original seals, and strictly follow the installation requirements for installation.