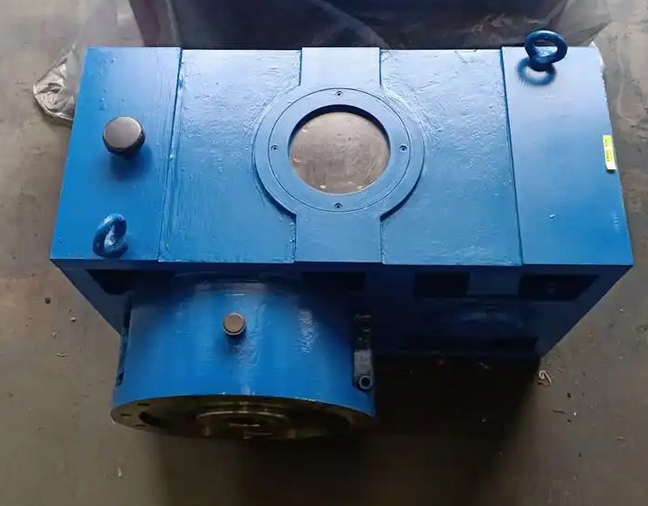

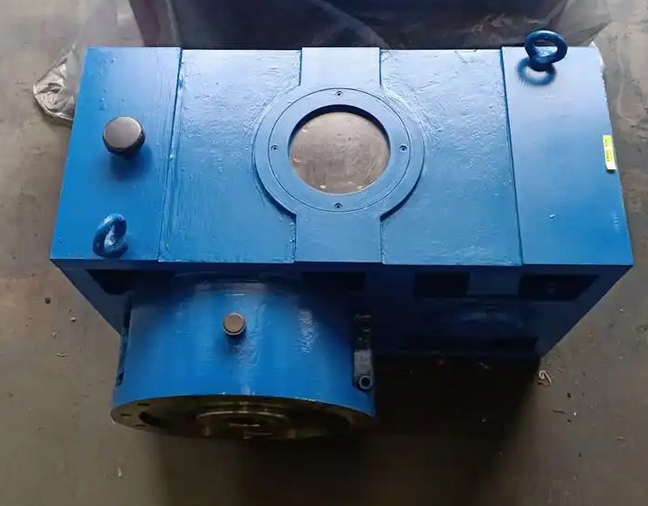

How does the lubrication and sealing system of the ZLYJ112-12.5-1 reducer used in plastic extruders work?

The working principle of the lubrication and sealing system of ZLYJ112-12.5-1 reducer for plastic extruder is as follows:

lubrication system

Oil pump forced circulation lubrication: ZLYJ112-12.5-1 reducer usually adopts an oil pump forced circulation lubrication system. The oil pump extracts the lubricating oil from the bottom oil pool of the reducer and transports it through pipelines to various lubrication points of the reducer, such as gear meshing and bearing parts. Lubricating oil forms an oil film in these areas, which reduces friction and wear.

Heat exchange and circulation: During the lubrication process, the lubricating oil absorbs the heat generated by the operation of components such as gears and bearings, and then flows back to the oil pool with the heat. Some models are required to add water cooling systems or air coolers to cool the lubricating oil in the oil tank. The cooled lubricating oil is pumped back to each lubrication point by the oil pump, forming a cycle to ensure stable internal temperature of the gearbox and prevent component damage or decreased lubricating oil performance due to high temperature.

Filtering and monitoring: The lubrication system of the gearbox usually also has a filter to filter impurities and metal shavings in the lubricating oil, preventing them from entering the lubrication point and exacerbating component wear. Some filters also come with a transmitter, which sends a signal when the filter element is severely clogged, reminding the user to stop the machine for cleaning or replacing the filter element. In addition, the electric contact pressure gauge configured according to the user's special requirements can monitor the working status of the oil pump. When the oil pump is damaged, the oil circuit stops supplying oil, and the electric contact pressure gauge loses pressure, there will be an electrical signal output, and the control circuit will automatically alarm and cut off the power supply to avoid burning the upper bearing due to oil shortage.

SEALING SYSTEM

Skeleton oil seal sealing: Skeleton oil seals are usually used to seal the input shaft and output shaft of the reducer. The skeleton oil seal consists of three parts: the oil seal body, the reinforced skeleton, and the self tightening coil spring. After the oil seal is installed on the oil seal seat and shaft, due to its inner diameter being smaller than the shaft diameter, there is a certain "interference fit", and the pressure of the oil seal blade and the contraction force of the self tightening coil spring will produce a certain radial tightening force on the shaft. When static, the spring pressure causes the sealing lip to tightly adhere to the shaft; During dynamic operation, the sealing lip automatically adjusts its fit through friction and centrifugal force to ensure sealing effectiveness under different working conditions. The oil film formed between the oil seal and the shaft can also prevent oil leakage and ensure heat dissipation and lubrication.

Mechanical seal: For some high demand applications, mechanical seals may be used, such as double end mechanical seal systems. Mechanical seals are usually composed of moving rings, stationary rings, clamping elements, and sealing elements. The moving ring rotates together with the shaft, and the moving ring and the stationary ring tightly fit to form a sealing surface. The spring provides pressure to ensure that the sealing end face always maintains tight contact, preventing medium leakage. In double end mechanical seals, the introduction of buffer circulation devices can better control the pressure fluctuations in the sealing chamber and improve the sealing effect.