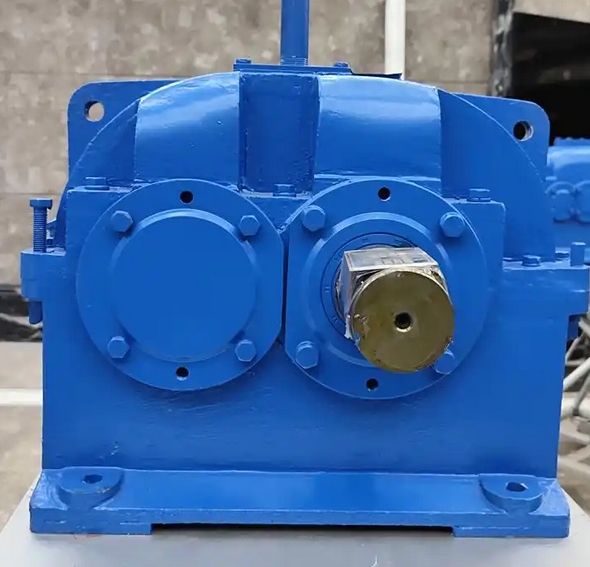

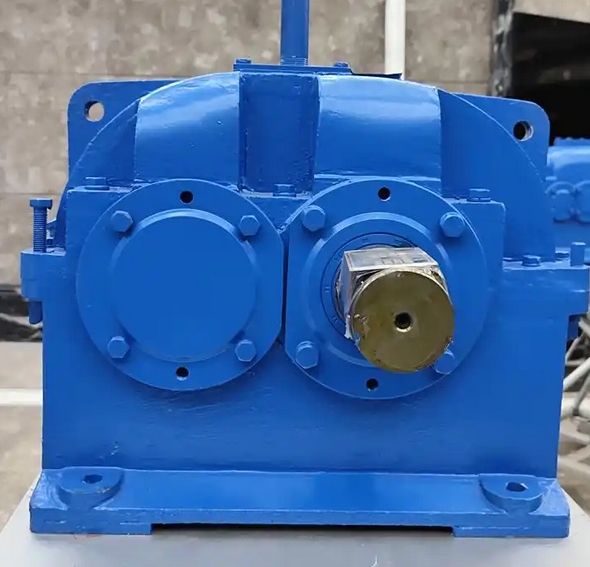

How to choose the appropriate assembly tool for the overhaul of ZDY280-5-1 hard tooth gear reducer

When repairing the ZDY280-5-1 hard tooth reducer, choosing the appropriate assembly tool requires consideration of multiple aspects. The following are some specific suggestions:

General tools

Wrench: Used for disassembling and tightening bolts and nuts. Choose the appropriate wrench according to the bolt specifications, such as a ring wrench, socket wrench, etc., to ensure that the wrench matches the bolt head shape perfectly and avoid damaging the bolt or wrench.

Screwdriver: Used for disassembling and installing smaller screws, handling delicate parts.

Hammer: You can choose a copper rod or rubber hammer, which is used to lightly tap certain components during assembly to assist in installation, but pay attention to the strength to avoid damaging the parts.

Pliers: Used for gripping, bending, or cutting metal wires, etc., which may be used when handling small parts or wires.

Vernier caliper: used to measure the dimensions of parts, such as shaft diameter, aperture, gear thickness, etc., to ensure that the dimensions of the parts meet the requirements.

Instrument

Feeler gauge: composed of a set of metal sheets of different thicknesses, used to measure the gap size between two components such as gear mesh clearance and bearing clearance.

Dial gauge: made using a precision rack and pinion mechanism, it displays the small displacement of the measuring rod by rotating the pointer on the meter head, and can accurately measure the size changes or clearance sizes of the measured components. It is commonly used to measure shaft runout, gear runout, etc.

Level gauge: used to detect the levelness of the gearbox housing to ensure smooth installation of the gearbox.

Torque wrench: According to the bolt specifications and manufacturer's requirements, use a torque wrench to tighten the bolt, ensuring that the specified torque value is reached and ensuring the reliability of the connection.

remover

Lamar: Used for disassembling interference fit components such as bearings and couplings. When selecting, it is necessary to ensure that the Lamar matches the component according to its size and type, in order to avoid component damage caused by improper Lamar selection.

Hydraulic jack: When disassembling and installing heavier components such as gearbox housing, a hydraulic jack can be used for lifting, which is convenient for operation.

Other tools

Lifting equipment: such as cranes, electric hoists, or chain hoists, used to lift heavier components of reducers, such as motors, boxes, etc., to ensure safe and orderly operation.

Pry bar: It can be used to pry open or move fastened components, breaking the tight connection between components, but care should be taken to avoid damaging the surface of the components during use.

Cleaning tools: such as brushes, compressed air blowers, clean cloths or tissues, etc., used to clean the dust, oil stains and other debris inside the gearbox, and keep the parts clean.

Paint or marking pen: used to mark the centering components or record the disassembly sequence, providing clear guidance for subsequent installation and ensuring the correct installation position of the components.