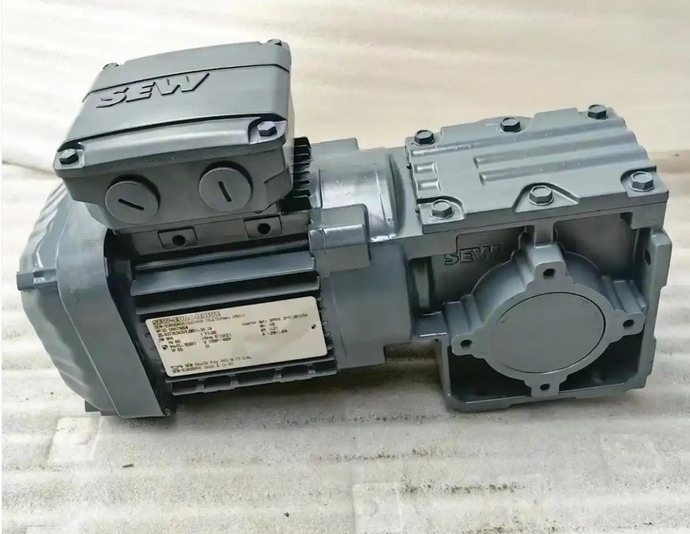

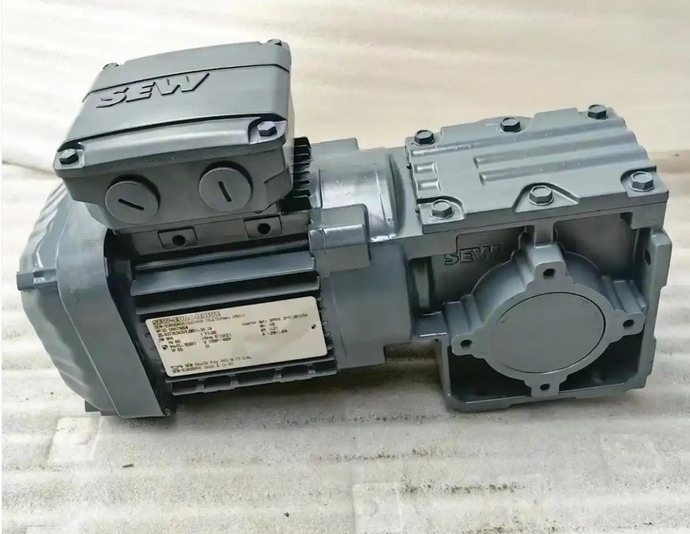

How to avoid lubrication pump failures in SEW reducers

To prevent the lubrication pump of SEW gearbox from malfunctioning, it is necessary to start from multiple aspects such as equipment selection, installation and commissioning, daily maintenance, oil management, and operation monitoring. The following are specific measures:

1、 Reasonable selection and correct installation

Match working condition requirements

According to the model, power, speed, and working environment (such as temperature and load) of the reducer, select the appropriate lubrication pump model to ensure that the pump's flow rate and pressure match the system requirements, and avoid overloading caused by "small horses pulling large vehicles".

Pay attention to the protection level of the lubrication pump (such as IP54/IP65), and choose a model with stronger sealing performance in harsh environments such as dust and humidity.

Standardize installation process

Installation position: Ensure that the lubrication pump is installed firmly and avoid vibration; The oil suction pipeline should be as short and well sealed as possible to prevent the inhalation of air.

Coupling alignment: The coupling between the motor and the pump needs to be accurately aligned (coaxiality error ≤ 0.05mm) to avoid pump shaft wear or breakage caused by eccentricity.

Pipeline connection: The oil pipeline should be clean and free of impurities, and the joints should be tightened and sealed (such as using raw tape or sealant) to prevent leakage.

2、 Strengthen daily maintenance and upkeep

Regular inspection and cleaning

Mechanical components: Check the wear of the pump shaft, impeller, and bearings every month. If there is any abnormal noise, increased vibration, or jamming, disassemble and repair or replace the components in a timely manner.

Electrical system: Check if the motor wiring terminals are loose and if the insulation of the circuit is good to avoid faults caused by poor contact or short circuits.

Filter: Clean or replace the oil suction filter and oil outlet filter every quarter (adjust the frequency according to the degree of oil contamination) to prevent impurities from blocking the oil circuit.

Lubrication and Sealing Management

Bearing lubrication: For the bearings of the lubrication pump itself (such as motor bearings and pump shaft bearings), regularly replenish lubricating grease (such as lithium based grease) according to the manufacturer's requirements to avoid dry grinding.

Seal replacement: Replace the pump body seals (such as shaft seals and O-rings) every 1-2 years to prevent oil leakage caused by aging.

3、 Oil quality control

Select appropriate lubricating oil

Strictly follow the SEW reducer manual to select lubricating oil (such as synthetic gear oil, viscosity grade ISO VG 220/320, etc.), and avoid mixing different brands or models of oil.

In low temperature environments (such as<-10 ℃), it is necessary to use low pour point lubricating oil (such as synthetic oil with added anticoagulant) to prevent the high viscosity of the oil from causing difficulties in starting the pump.

Oil cleanliness management

Before injecting new oil, it needs to be filtered (with an accuracy of ≤ 25 μ m) to avoid impurities during transportation or storage.

Regularly check the oil contamination level (recommended every six months), use an oil particle counter to detect impurity content, and filter or replace the oil if it exceeds ISO 18/16 level.