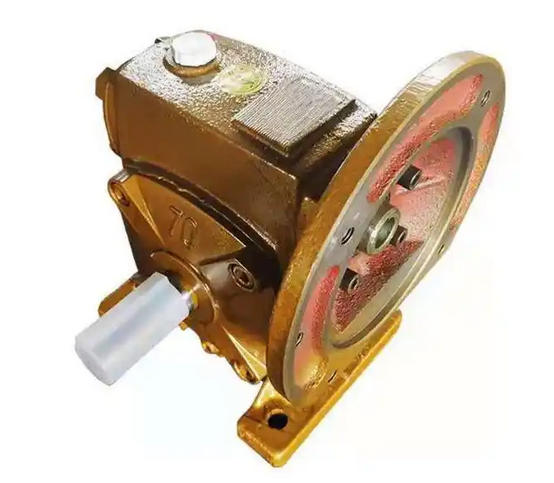

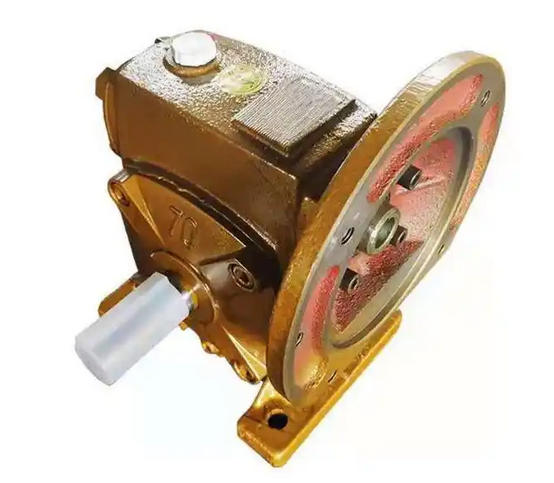

What damage can high operating temperature cause to the worm gear of WPDS135-30-B reducer

WPDS135-30-B, as a worm gear reducer, has mostly tin bronze worm gears and alloy nitride steel worm gears. These reducers have obvious sliding friction and are prone to heat generation. High operating temperatures can cause chain damage to the worm gear, which can also lead to problems with surrounding components, further exacerbating the damage to the worm gear. The specific details are as follows:

Lubrication failure leads to severe wear on the tooth surface: an increase in temperature can cause a significant decrease in the viscosity of the specialized lubricating oil for worm gears and worms, resulting in a thinner or even cracked oil film, which cannot effectively isolate the metal meshing surfaces of the worm gear and worm, leading to boundary friction or even dry friction. At the same time, high temperature will accelerate the oxidation of lubricating oil, generating deposits such as sludge and gum. These impurities mixed into the meshing surface will form abrasive wear, resulting in a large number of scratches and pitting on the tooth surface. Moreover, for every 10 ℃ increase in oil temperature, the oxidation rate of lubricating oil will increase by about twice, and the wear rate will also sharply increase.

Tooth surface is prone to adhesion and biting: High temperatures can soften the surface metal of tin bronze worm gears, and although the worm gear is made of alloy steel, its hardness will also decrease to a certain extent at high temperatures. At this point, the friction coefficient of the meshing surface will significantly increase, and under heavy load conditions, softened metal is prone to adhesion. If the high temperature persists, the adhesive area will be torn along with the transmission, forming adhesive wear. In severe cases, tooth surface meshing may occur, and even cause the worm gear to get stuck, resulting in equipment shutdown and failure.

Early fatigue peeling on the tooth surface: Long term high temperature environment can reduce the mechanical properties of the worm gear material, such as decreased toughness of the worm gear copper alloy and decreased surface hardness of the worm gear. When the worm gear is engaged, the tooth surface will bear repeated contact stress, and high temperature will amplify the destructive effect of this stress. Small fatigue cracks appear on the tooth surface first, and then the cracks gradually expand, ultimately leading to pitting and peeling of the metal on the tooth surface, greatly reducing the smoothness of the transmission and possibly causing abnormal vibration.

Deterioration of meshing accuracy exacerbates eccentric wear: The thermal expansion coefficients of the worm gear and worm gear are different, with the thermal expansion coefficient of the worm gear being approximately half of that of the worm gear. There is a difference in the degree of thermal deformation between the two at high temperatures, which can cause the originally precise axis line to shift and abnormal changes in the meshing clearance. This reduces the contact area during meshing, concentrates local stress, not only produces obvious abnormal noise, but also causes local tooth surface wear speed to far exceed other parts, resulting in problems such as eccentric wear and tooth biting, further damaging the transmission structure of the worm gear.

Associated damage to seals indirectly exacerbates pollution and wear: The oil seals, gaskets, and other components of the gearbox are mostly made of rubber material, and high temperatures can cause them to rapidly age, harden, and lose elasticity, leading to seal failure. External dust, water vapor, and other impurities can enter the interior of the casing through sealed gaps and mix into the lubricating oil. After these impurities enter the meshing surface of the worm gear, they will further intensify abrasive wear. At the same time, water vapor may also work together with high temperature, causing slight corrosion on the surface of the worm gear. The copper alloy of the worm gear may also have corrosion spots, causing double damage to the tooth surface of the worm gear.