Apart from maintenance cycles, what other factors can affect the lifespan of the RF47-1.5KW-60 reducer?

In addition to maintenance intervals, the following factors can also affect the service life of the gearbox:

Usage environment: Factors such as temperature, humidity, gas, dust, and corrosion in the environment have a significant impact on the gearbox. High temperatures can cause lubricating oil to deteriorate and accelerate component wear; A humid environment may cause rusting of internal components; An environment with high dust or corrosive gases can affect the sealing of the gearbox, causing lubricant leakage or deterioration.

Load situation: The greater the load that the reducer is subjected to, the more complex the stress situation, the higher the working temperature, and the more severe the wear and fatigue phenomena. If it is in an overloaded state for a long time, its service life will be significantly shortened.

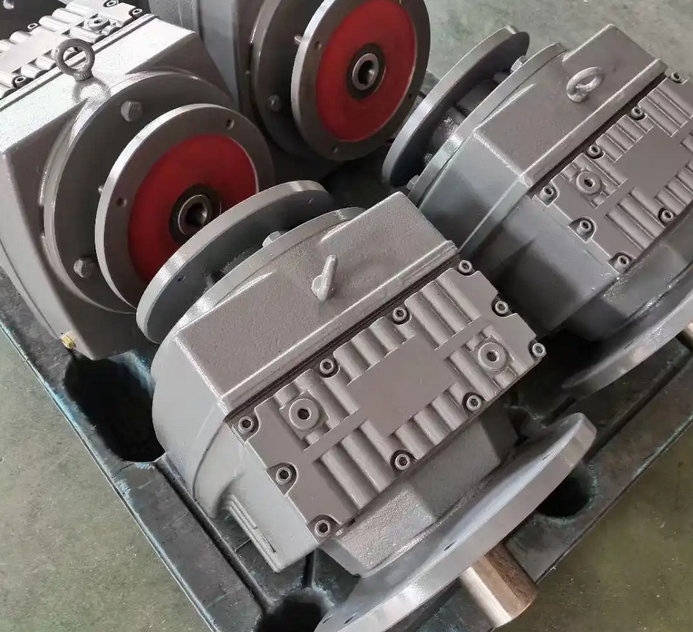

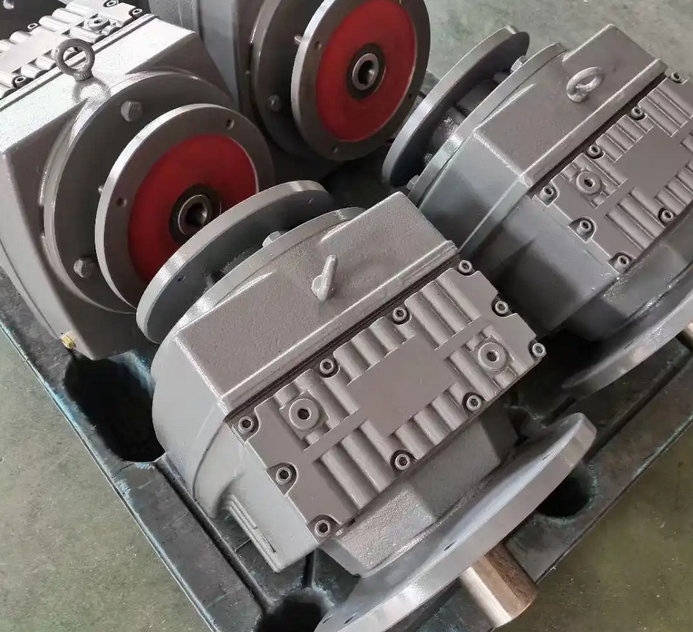

Gear transmission structure: As an important transmission component of the reducer, gear overload, imbalance, clearance, wear, and poor accuracy can lead to increased noise and vibration in gear transmission, and even serious consequences such as tooth surface fracture and bearing failure, directly affecting the performance and service life of the reducer.

Lubrication status: Reasonable lubrication methods, selection of appropriate lubricants, and regular replacement and replenishment of lubricating oil are crucial for extending the service life of the gearbox. If the lubrication is poor, the wear and friction between the moving pairs will intensify.

Smooth operation: The impact and vibration during startup and shutdown can impose additional loads on the internal components of the gearbox, leading to fatigue damage. Frequent start stop or severe vibration can increase the wear of the gearbox and reduce its service life.

Design and manufacturing quality: Whether the design of the reducer is reasonable and the quality control during the manufacturing process will directly affect its service life. High quality manufacturing processes, such as precision machining and assembly, can improve the durability of the gearbox and reduce wear during operation.