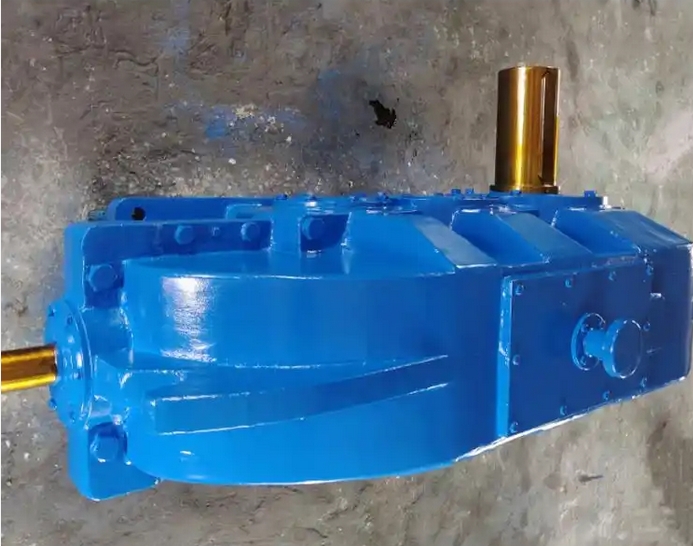

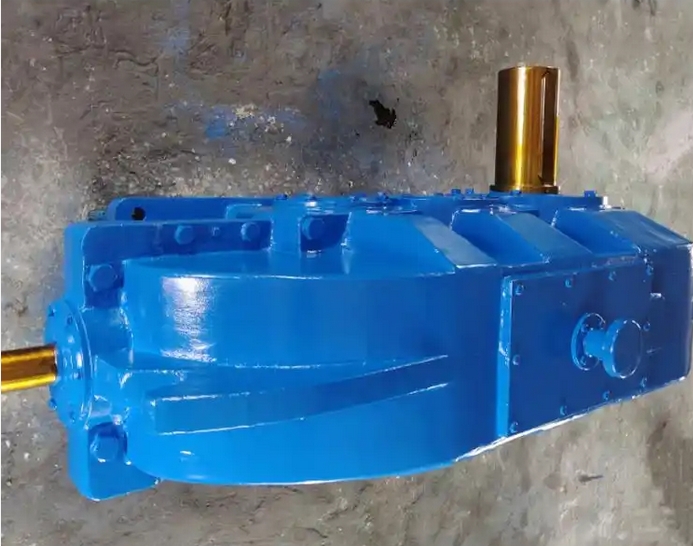

Bearing damage can affect the DCY315-25-3 gear reducer in several ways.

The bearings in the DCY315-25-3 reducer play an important role in supporting rotating components, reducing friction, maintaining accuracy, dissipating heat, and reducing vibration. Bearing damage will have the following effects on the DCY315-25-3 gearbox:

Increased vibration: After bearing wear or raceway damage, it can disrupt the balance and stability of rotating components, causing abnormal vibration during gearbox operation, especially at high speeds. This not only affects the use of the gearbox, but may also cause loosening and damage to other mechanical components.

Increased noise: Damaged bearings can disrupt the contact balance between rolling elements and raceways, resulting in abnormal noises such as buzzing and knocking during operation.

Temperature rise: Bearing damage will increase the friction coefficient, generate more heat, and also affect the heat dissipation function of the bearing, leading to an increase in the internal temperature of the gearbox. Long term operation at high temperatures may cause deterioration of lubricating grease, thermal expansion of components, and further exacerbate bearing wear, even leading to bearing jamming.

Decreased transmission efficiency: Bearing wear, cracks, or fractures can increase frictional resistance during the transmission process, leading to a decrease in the efficiency of the gearbox when transmitting power. This may result in reduced torque and unstable speed, making it difficult to effectively transfer power from the input shaft to the output shaft.

Decreased accuracy: The DCY315-25-3 reducer has certain requirements for transmission accuracy. Bearing damage can cause an increase in clearance between transmission components, affecting transmission accuracy and potentially leading to an increase in positioning error, thereby reducing the machining or operational accuracy of related equipment.

Equipment failure or even shutdown: If the bearings are severely damaged, it may cause the gearbox to completely stop running or get stuck, interrupting the entire production process and having a serious impact on production. In addition, long-term bearing failures may also pose other safety risks, such as sudden equipment damage causing personal injury or other property damage.