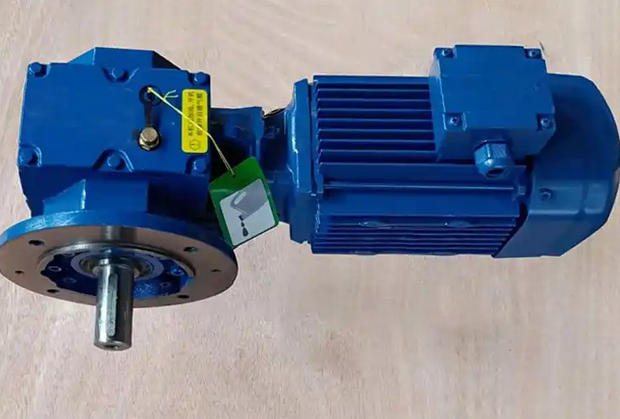

What are the consequences of gear damage in SF77-25.93-4KW hard tooth reducer

Gear damage to the SF77-25.93-4KW hard tooth reducer can result in the following consequences:

Reduced transmission efficiency: After gear damage, such as tooth surface wear and increased meshing clearance, the gear will experience slipping, impact, and other phenomena during transmission, resulting in increased losses during energy transfer and a transmission efficiency lower than 85% of the rated value.

Increased vibration and noise: Damage such as gear wear, tooth breakage, and tooth surface adhesion can disrupt the normal meshing state of gears, causing uneven stress and vibration during operation, resulting in increased noise, such as sharp friction or periodic impact sounds. At the same time, the overall vibration amplitude of the machine will also exceed the normal range, such as amplitude>0.1mm/s.

Temperature rise: Due to poor meshing and increased friction caused by gear damage, the internal heat of the gearbox will increase. However, if the heat dissipation remains unchanged, the temperature of the gearbox will rapidly rise, which may lead to a decrease in the performance of the lubricating oil and further exacerbate gear wear.

Insufficient output torque: Gear damage can lead to a decrease in the load-bearing capacity of the gear, making it unable to effectively transmit power, resulting in insufficient output torque of the reducer, which cannot meet the normal working requirements of the equipment and affect its normal operation.

Lubricating oil pollution: During the process of gear damage, metal debris and other impurities will be generated, which will mix into the lubricating oil, causing lubricating oil pollution, blackening of the oil, and a decrease in viscosity of more than 15%, thereby affecting the lubrication performance of the lubricating oil and accelerating the wear of gears and other components.

Equipment shutdown and damage: If the gears are severely damaged, such as broken teeth, it can cause the equipment to suddenly shut down and fail to operate normally. In addition, gear damage may also cause damage to other components such as bearings, shafts, etc., further expanding the scope of equipment failure, increasing maintenance costs and downtime.