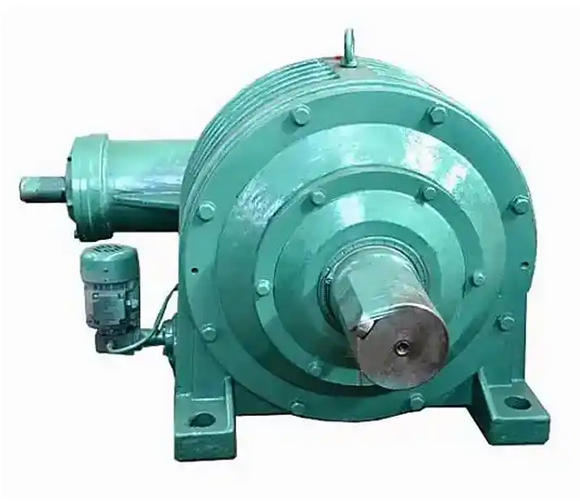

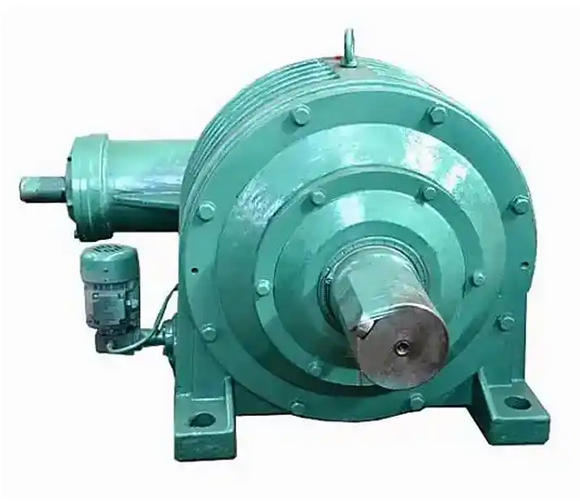

How to determine whether the vibration of NGW-S123-63 planetary gear reducer exceeds the standard

To determine whether the vibration of NGW-S123-63 planetary gear reducer exceeds the standard, a comprehensive analysis should be conducted based on measurement data, operating status, and industry standards. The specific methods are as follows:

1、 Vibration numerical measurement and judgment

Measurement parameters

Use a vibration tester to measure the root mean square (RMS) of the vibration velocity on the surface of the casing, and prioritize selecting radial/axial measuring points near the bearing seat

Rigid support equipment with a vibration speed ≥ 4.5mm/s is considered to exceed the standard, while flexible support equipment with a vibration speed ≥ 7.1mm/s is considered to exceed the standard

Industry standard reference

In the ISO 10816-1/3 standard, the alarm threshold for A/B/C level equipment is usually set at 2.8mm/s (it is recommended to be stricter for high-speed light load equipment)

If the manufacturer's technical manual specifies stricter standards (such as ≤ 2.5mm/s), priority should be given to implementation

2、 Vibration characteristic analysis

Abnormal frequency

The normal vibration frequency should be consistent with the gear meshing frequency (speed x number of teeth). If high-frequency noise (such as>1000Hz) or low-frequency impact (such as bearing failure frequency) occurs, gear wear or bearing damage should be investigated

Edge band characteristics

The appearance of sidebands on both sides of the meshing frequency in the spectrum (such as frequency doubling modulation) may indicate local defects (such as pitting) or uniform wear of the gear

3、 Auxiliary judgment of operating status

Temperature and noise

Vibration accompanied by temperature>80 ℃ or abnormal noise (such as "click" sound, "scream" sound) indicates gear/bearing failure

When the oil temperature exceeds 90 ℃ and the vibration exceeds the standard, it is necessary to check the lubrication system and heat dissipation conditions

Load and speed

Vibration intensifies during sudden load changes or speed fluctuations, which may be caused by overload or resonance

If the output shaft speed drops by more than 10% or the motor current exceeds the set value by 15%, it is necessary to investigate the transmission efficiency issue

4、 On site rapid detection method

Simple vibration diagnosis

Manually rotate the input shaft. If you feel "lagging" or uneven resistance, it may indicate abnormal gear meshing

Check the contact spots on the gear tooth surface after stopping the machine (along the tooth length ≥ 80%, along the tooth height ≥ 70%)

Online monitoring system

If the vibration value increases by more than 50% in the short term or remains high, immediate shutdown and maintenance are required