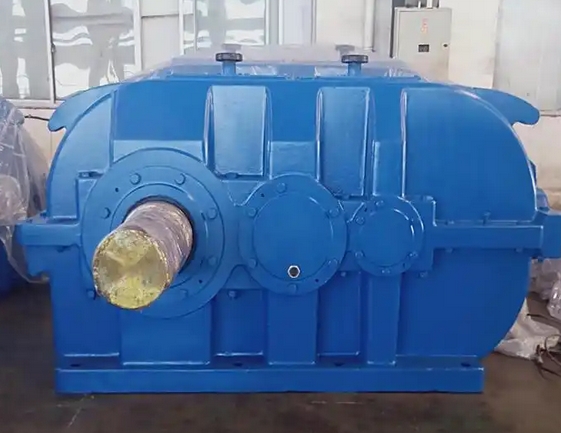

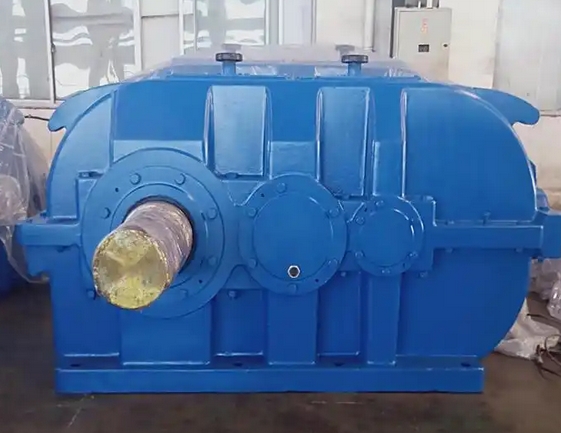

How to select the appropriate nitriding process for the DCYK250-20-3 gear reducer

To choose a suitable nitriding treatment process for DCYK250-20-3 gear reducer, the following aspects need to be considered:

Gear material: The gears of DCYK250-20-3 gear reducer are usually made of medium carbon steel or medium carbon alloy steel, such as 40Cr, 42CrMo, etc. If steel containing alloy elements such as Al, Cr, Mo, etc. is used, such as 38CrMoAl, it is more conducive to forming high-quality nitride layers, and gas nitriding or ion nitriding processes can be prioritized; For ordinary carbon steel or low-alloy steel, gas nitriding can also be used, but the nitriding temperature and time need to be adjusted appropriately, or nitrogen carbon co nitriding (soft nitriding) process can be selected to obtain better layer properties.

Service conditions:

Load situation: If the gearbox operates under heavy load conditions, it is required that the gear has a deep nitriding layer and high hardness to improve wear resistance and fatigue strength. Gas nitriding multi-stage nitriding process or ion nitriding process can be selected to obtain a nitriding layer of 0.3-0.6mm or even deeper, with high hardness. If the load is light and the requirements for the depth and hardness of the infiltration layer are relatively low, ordinary gas nitriding or nitrogen carbon co infiltration processes can be considered. Although the infiltration layer is shallow, it can meet the requirements of light load.

Working environment: Working in an environment with corrosive media requires the nitride layer to have good corrosion resistance. The process of ion nitriding or gas nitriding followed by post oxidation treatment is more suitable to improve the corrosion resistance of the gear surface. When working in high temperature environments, nitriding processes that can maintain hardness and stability at higher temperatures should be selected, such as high-temperature nitriding processes for high alloy steel in gas nitriding or ion nitriding processes.

Accuracy requirement: As a general industrial gear reducer, DCYK250-20-3 has certain requirements for accuracy. To control the amount of deformation, ion nitriding is a better choice in the selection of nitriding process due to its advantage of small deformation. If gas nitriding is used, strict control of process parameters is required, such as nitriding temperature should be about 50 ℃ lower than the tempering temperature of quenching and tempering, and sufficient stress relief treatment should be carried out before nitriding to reduce deformation.

Production cost: Gas nitriding equipment is relatively simple and cost-effective, but the processing time is long; Ionic nitriding equipment is complex and requires high investment, but it has short processing time and good quality. The overall cost needs to be balanced based on production batch size and specific requirements. If the production batch is large, the cost control requirements are high, and the quality requirements for nitriding are not extremely strict, gas nitriding may be more suitable; If high quality and production efficiency are required, ion nitriding may have more advantages in the long run, although the cost is high.

Production efficiency: Ion nitriding can shorten the nitriding cycle appropriately. For mass production and situations that require high production efficiency, ion nitriding technology has more advantages. The multi-stage nitriding process in gas nitriding has a shorter time compared to isothermal nitriding, but overall it is still longer. If the production task is not urgent and the efficiency requirements are not high, the gas nitriding process can also meet the demand.