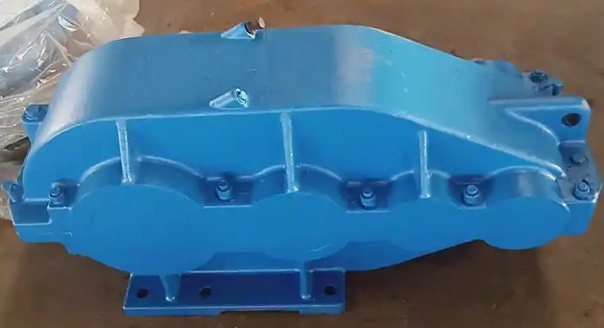

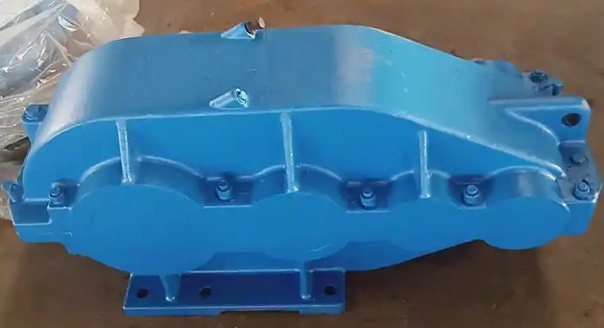

Introduce the structure of the ZSC750-54.5-3 medium-hardened gear reducer.

The ZSC750-54.5-3 medium hard gear reducer is mainly composed of gears, shafts and bearing combinations, housing, accessories, etc. The following is a detailed introduction:

Gear, shaft and bearing combination

Gear: ZSC750-54.5-3 reducer adopts involute cylindrical gears, which may include spur gears or helical gears. The material is usually high-quality alloy steel, such as 40Cr, which has undergone heat treatment processes such as quenching and tempering. The tooth surface hardness can reach HRC40-45, with high strength, wear resistance and fatigue resistance. The modulus, number of teeth, and other parameters of gears are designed according to the transmission ratio and load requirements, and power transmission and deceleration functions are achieved through mutual meshing.

Shaft: The input shaft, output shaft, and intermediate shaft are generally made of high-strength carbon steel or alloy steel, and undergo precision machining and heat treatment to ensure the strength, stiffness, and dimensional accuracy of the shaft. The shaft is machined with key slots, splines, and other structures for installing gears, couplings, and other components, and transmitting torque. Install bearings at both ends of the shaft to support its rotational motion.

Bearings: Rolling bearings such as deep groove ball bearings, tapered roller bearings, etc. are usually used to support the rotation of the shaft and withstand radial and axial loads. The selection of bearings is determined based on factors such as shaft speed, load size, and direction to ensure smooth operation and longer service life of the gearbox. In order to prevent lubricant leakage and external dust from entering, a sealing element is installed between the bearing end cover and the extended shaft.

box

Materials and Manufacturing Process: The casing is an important component of the gearbox, generally made of gray cast iron, which has good casting and vibration reduction properties. For heavy loads or impact loads, cast steel casing can also be used. In order to simplify the process and reduce costs, the gearbox produced as a single unit can adopt a box body welded with steel plates.

Structural design: In order to facilitate the installation and disassembly of shaft components, the box body is made into a horizontal split along the axis line, and the upper box cover and lower box body are connected as a whole with bolts. The connecting bolts of the bearing seat should be as close as possible to the bearing seat hole, and the protrusion next to the bearing seat should have sufficient support surface to place the connecting bolts and ensure the wrench space required for tightening the bolts. To ensure that the box has sufficient rigidity, support ribs are added near the bearing holes. To ensure the stability of the gearbox when placed on the foundation and minimize the mechanical processing area of the box base plane, the box base generally does not use a complete plane.

attachment

Lubrication system: including lubricating oil tank, oil pump, oil gauge, oil nozzle, etc. The lubricating oil tank is used to store lubricating oil, and the oil pump delivers the lubricating oil to various gear and bearing parts for lubrication and cooling, in order to reduce friction and wear and extend the service life of the gearbox. The oil gauge is used to display the oil level height, making it easy to check the amount of lubricating oil, while the oil nozzle is used to add or replace lubricating oil.

Sealing device: Sealing devices such as sealing rings, gaskets, oil seals, etc. are installed at various joint surfaces and shaft extensions of the reducer to prevent lubricating oil leakage and prevent external dust, moisture, and other impurities from entering the box, ensuring a clean and good lubrication environment inside the reducer.

Heat dissipation device: Due to the heat generated by the reducer during operation, in order to prevent high oil temperature from affecting the performance and service life of the reducer, some reducers are also equipped with heat dissipation devices, such as heat sinks, cooling water pipes, etc., to increase the heat dissipation area and improve the heat dissipation effect.

Lifting ears or rings: Install lifting ears or rings on the top or side of the box to facilitate the lifting, handling, and installation of the gearbox.