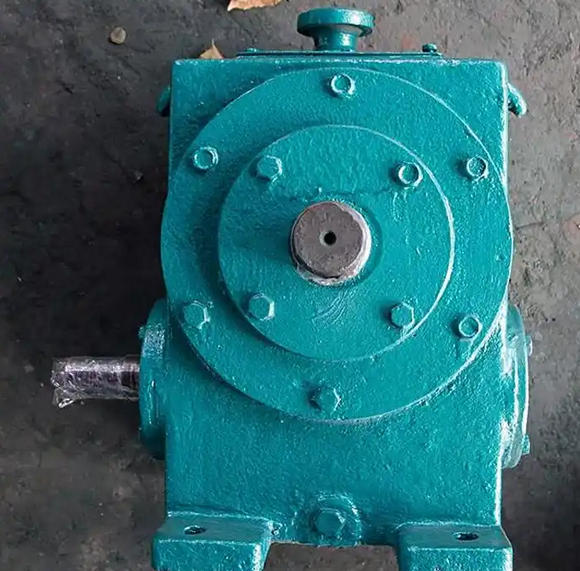

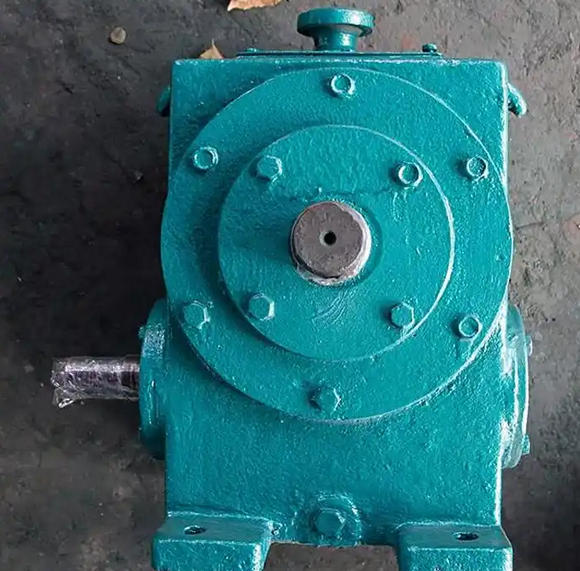

Maintenance points of WD120-23.5-1 worm gear reducer

WD120-23.5-1 is a single-stage worm gear reducer with a worm gear located below, a center distance of 120 mm, and a nominal speed ratio of approximately 23.5. It is suitable for situations that require high speed ratios, smooth transmission, and may have reverse self-locking; However, friction heating and high alignment requirements require strict lubrication and temperature rise management.

Maintenance points (immediate execution)

Installation and alignment

Horizontal/firm installation, use elastic couplings for input and toothed couplings for output, strictly prohibit hammering for installation and disassembly; The overall alignment error is ≤ the allowable compensation amount of the coupling.

Flexible manual turning after installation; No load for 1-3 hours, intermittent operation with partial load, and then full load, during which temperature rise and noise are monitored.

Lubrication and oil change

First 300-500 hour oil change; After continuous operation, change the oil every 2000-3000 hours or 6 months, ≤ 10 hours/day every 4000 hours or 12 months; Change the oil and clean it with the same brand before adding new oil.

Check the oil level to 2/3 of the oil window when the machine is stopped; Prioritize extreme pressure type worm gear special oil, increase viscosity according to the manual or switch to synthetic oil for low temperature or high/heavy load.

operation monitoring

Temperature rise ≤ 60 K, oil temperature ≤ 85-100 ℃; Immediately stop the machine for troubleshooting in case of abnormal temperature rise/noise/vibration/leakage.

If the ambient temperature is above 40 ℃ or continuously at full load, strengthen ventilation/air cooling or forced lubrication.

periodic inspection

Week/month: Appearance, oil level/quality, bolts, leakage.

Season: Vibration/temperature trend, noise, and if necessary, oil sample testing (viscosity, acid value, moisture, ferrography).

Half a year/year: Disassemble and inspect seals, bearings, meshing clearances, and contact spots; Replace worn parts and run in before loading.

Environment and working conditions

In dusty/humid/corrosive environments, strengthen protection and sealing, and shorten the oil change and inspection cycle.

Preheat or heat up before starting at low temperatures to avoid poor lubrication with high viscosity oil.